In our last post about ‘How to optimize Procurement Performance’ we addressed 4 out of 7 key PPM areas:

- Precise and reliable spend forecasting

- Multidimensional spend analysis (monitor direct & indirect spend, maverick spending etc.)

- Supplier, vendor lifecycle & risk management (evaluation, (re)negotiation, monitoring etc.), contract management (negotiation, monitoring etc.) and

- Savings management (precise forecasts, monitoring, initiatives etc.)

Now we want to focus on the remaining 3 suggestions of our guided Procurement Performance workflow:

- the importance of integrating procurement and S&OP processes, and the collaboration with Finance and other departments

- how to keep track of price development

- ensuring that goods and services are properly acquired, so that company’s strategic objectives are fulfilled = fully integrated business planning

5. Why is it indispensable to integrate Procurement Performance and S&OP?

Sales planning provides information on expected demand for the various products. Forecasts, regularly originating from top-down revenue targets, need to be translated in volumes or units. Those need to be translated into raw materials via BOM (see figure 2). The question of place and time of use is essential for the success of a company and should be managed with appropriate care.

To forecast direct spend, any procurement performance analyst needs to closely collaborate with S&OP departments. We are experts with knowledge and experience in both the procurement and supply chain discipline, emphasizing integrated financial planning and performance. In smartPM’s solutions both, procurement and S&OP are seamlessly connected (see figure 1).

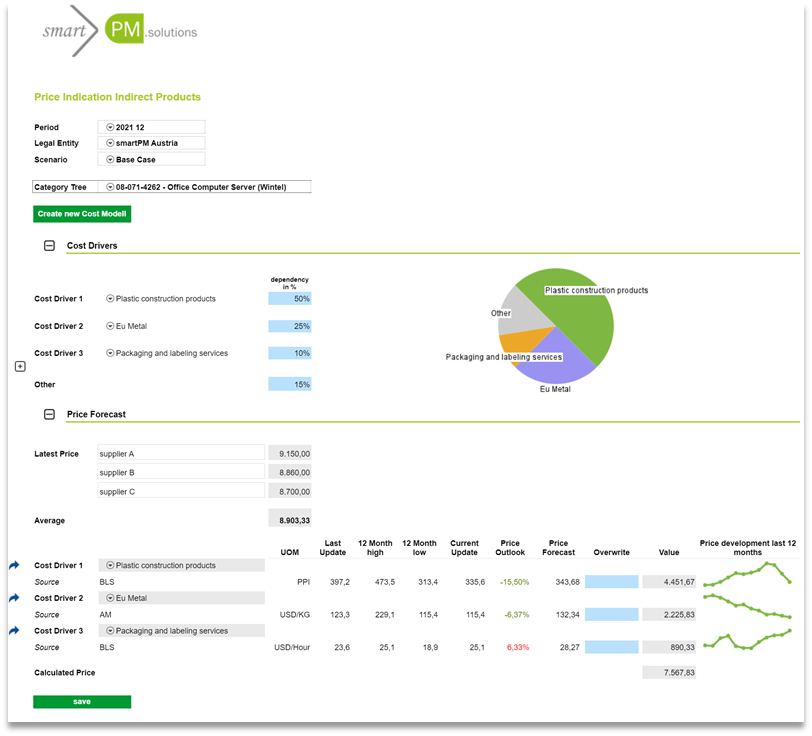

6. Are you keeping track of price development and cost drivers?

Irrespective of direct or indirect spend, price change indicators like PPI, raw material market prices or labor cost developments are relevant for an efficient Procurement Management. A lack of information in this regard leads to lower leverage when it comes to price negotiation, therefore produces avoidable costs and undermines important Procurement KPIs.

smartPM.solutions’ Procurement Performance Management tool can keep track of historical price information. It displays prices on an average annual-, quarterly-, monthly- or weekly basis and compares them to actual price propositions. Our Machine Learning (ML) algorithms (e.g. Neural Networks) recommend certain price assumptions, but can be overruled by “Human Intelligence”. As an add-on, the price tracking module can be connected to external (macro-economic) data and set in relation to certain cost drivers. This gives analysts a predictive foresight to initiate the procurement process at the ideal time and save financial resources (see figure 3).

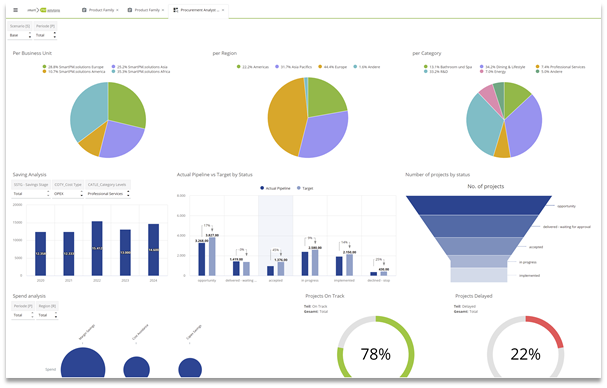

7. Are you able to answer ad-hoc questions from management and simulate decisions upfront?

This is where fully integrated business processes show their full potential. smartPM´s reports and dashboards provide the information you need in your role. Dashboards are easy to configure and individually adaptable. Reports can be standardized and support near time updates. By analyzing real-time procurement data, meaningful insights are gained, and effective, fact-based decision making is supported.

Automated spend analysis, vendor delivery timeliness, quality of materials, time to resolve problematic orders, purchase order values, invoice reports and dashboards to identify savings and cost reduction opportunities etc. are clearly visualized and easy to understand. Key KPIs help to discover better purchasing options, reduce bottlenecks and improve strategic sourcing, even on the road: our one client-integration allows all kinds of devices (like smartphones or tablets) access to the system (see figure 4).

Extended scenario analysis lets you simulate decisions on your P/L, BS and CF upfront, so you get the big picture. What else can procurement departments wish for? Get in touch with us in an expert talk and share your opinion about our approach and what you experienced so far in digitalizing procurement workflows.